Main Menu

- About CTTC

- Team CTTC

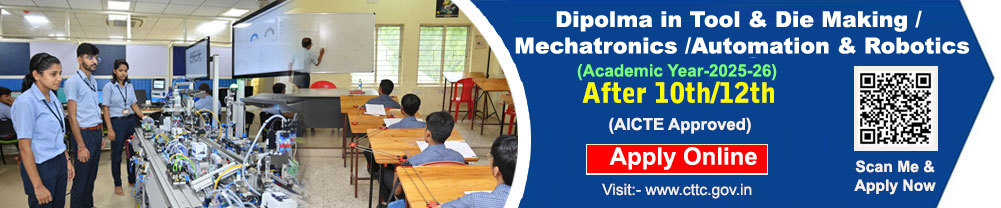

- Diploma Courses

- Online Courses Registration

- Long Term Courses

- Short Term Courses

- CTTC-Incubator

- SFURTI

- Patent,Trademark and Design Reg (IPFC Service)

- CHAMPIONS

- Six Sigma Program

- SAP Business One

- Samsung Arise2 Course

- Facilities

- Annual Report

- Chief Vigilance Officer

- Certified Trainer

- Placement

- Photo Gallery

- Recruiter

- Feedback

Download Links

About CTTC

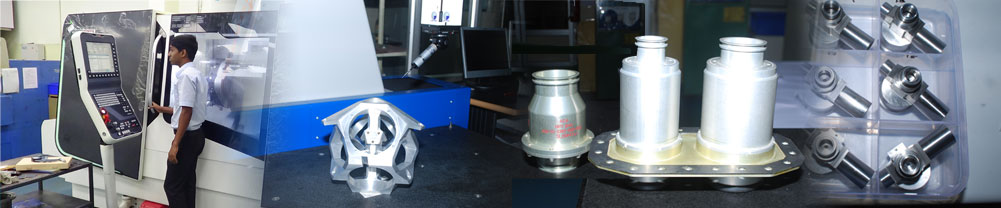

In the present scenario of industrialization; particularly in the engineering field, requirements of specialized tools, dies, jigs, fixtures, moulds, gauges and other precision components are indispensable. Simultaneously demand for quality Tool makers, Tool & Product Designers, Skilled manufacturers, PLC & Industrial Automation engineers and Maintenance Engineers is also growing rapidly. Central Tool Room & Training Centre (CTTC), Bhubaneswar is one of such training, production, design and consultancy centre established in technical cooperation programme between Govt. of India & Govt. of Denmark to meet the above requirements. The excellent infrastructural facilities like land, building etc. have been contributed by Govt. of Orissa. Training activities started in 1991 and Tool production in 1995.

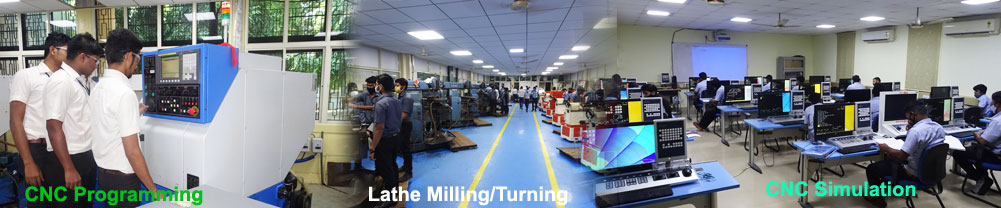

CTTC is unique in imparting industry oriented long & short term training programmes on CAD/CAM, Tool Design & Manufacturing, Tool & Die Making, CNC Programming & Machining, Machine Maintenance, CCNA, Industrial Automation, VLSI, Hardware & Networking Management, ITI (Machinist/Welder) etc. CTTC believes in PRACTICE MAKES PERFECT.

Vision

To become Internationally Acclaimed Centre of Excellence in the area of Design, Development & Manufacturing of Quality Tools & Components, Project Consultancy & Skill Development.

Mission

Promote Growth & Development of Micro, Small & Medium Enterprises through Technological & Skilled Manpower Support.

MSME Tool Room at a Glance :-

Machinery Investment:

Total plant area: 11.3Acres

Total Power Supply:

1. Well Equipped Computer Labs:

2. Knowledge/ Information Centre

3. Guest House & Hostel Facility for both girls and boys

. The Objectives of MSME Tool Room include.. To impart long-term and short-term training to youngsters in the field of Tool & Die making course with the latest technologies (and other allied Engineering trades) both for fresher's and personnel already engaged in this field. To provide Consultancy Services primarily to Small scale Units in the field of Tool Engineering aimed at improving the productivity of the Small Scale Units. To provides common facility services in precision machining / heat treatment and other technical engineering know-how in tooling to Small Scale Industries in the Country. To design and manufacture Moulds, Tools, Dies, Jigs Fixtures, etc. of high precision quality.. We undertake Design and Manufacturing of Jigs, Fixtures, Gauges, Die Casting Dies, Press Tooling and Plastic Moulds for the Automobile and Engineering sectors and machining of precision components. Along with this we also conduct 4 years Diploma in Tool and Die Making, 2 years ITI, and various short term training courses on CAD/ CAM/ CAE, CNC, PLC, Maintenance, etc.